Fuel Quality Monitoring in Fuel Storage and Dispensing

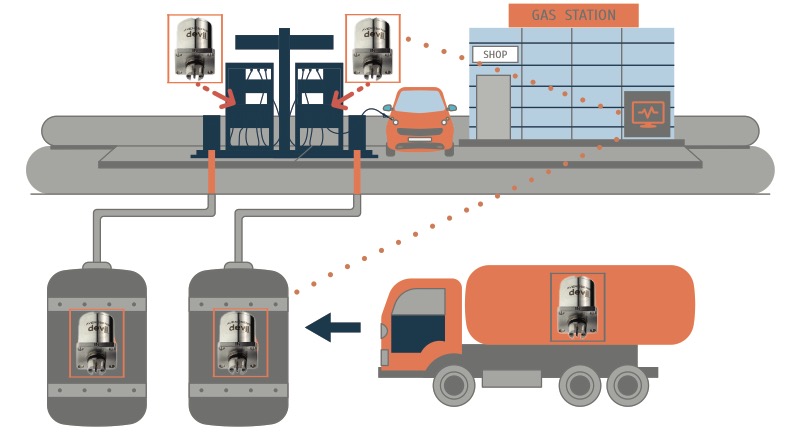

The fuel distribution industry faces many challenges when it comes to storage and dispense including water contamination and temperature variations.

The innovative, patented sensor DEVIL provides a high performance, cost-effective method for in-line or in-tank density and viscosity measurement for monitoring fuel quality.

By actively monitoring fuel quality, fuel suppliers can spot changes in fuel quality sooner to protect the brand image, maintain customer loyalty and reduce financial risk.

Accurate invoicing & savings. DEVIL detects in real-time the slightest changes in fuel composition, insuring storage and deliver of high quality fuels.

Constant quality. The continuous measurement of fuel density might enable a switch from volumetric to mass fuel sales for more accurate inventory accounting.

Increased brand image. Thanks to constant fuel quality monitoring customer loyalty is improved.

Robustness. Our solution is designed for operating in hazardous environments, mounted in the elements and accurate over a wide temperature range.

|

|

Features:

- Online measurement of the liquid density for online calculation of energy delivered

- Fast and reliable communication to the operator to monitor of density during fuel delivery

- Easy implemented into existing dispenser systems due to the unmatched small footprint, electrically safe operation and the various mounting options

- No change in the flow delivery rate and no additional pressure loss in the dispensing system

Still hesitating? Contact our technical engineers to discuss your project sales.wikatech@wika.com