JET FUEL MONITORING FOR SAFE FLIGHT & OPERATIONS

The goal of Air Transport company is to supply the safe amount of fuel per flight while reducing the cost of carrying extra fuel weight. The challenge comes from density and viscosity of jet fuel that can vary greatly based on the source of the crude used to refine the fuel and on temperature and the operation of the refinery. This is why the measurement of both parameters is important for the operation of a jet engine; for reducing extra fuel weight and ensuring flight safety. DEVIL sensor is perfectly suited for installations from the fuel farm to on-board the aircraft.

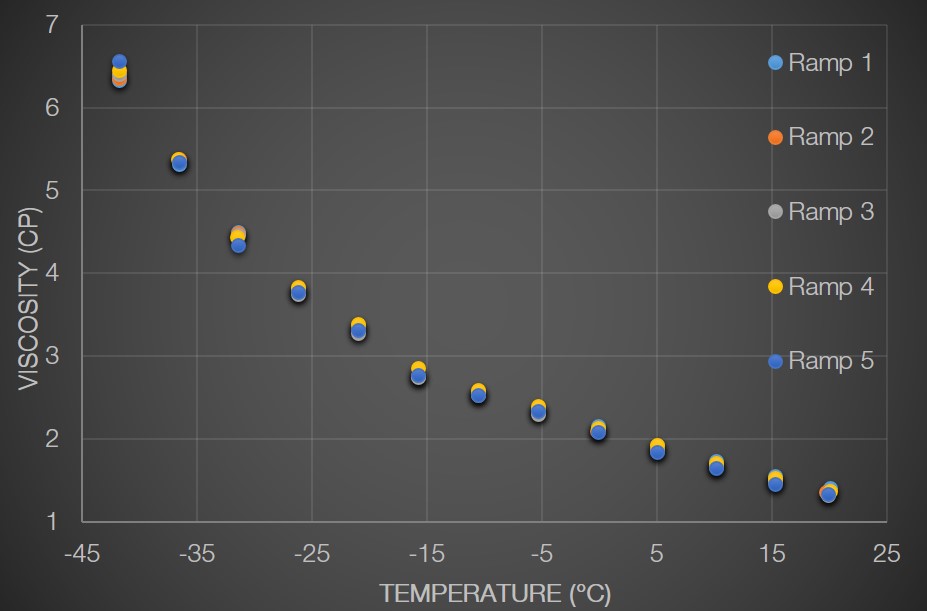

Low temperature resistant. Up to +95°C ambient temperature down to -40°C the sensor shows excellent repeatability

Small footprint for easy integration. DEVIL can be installed in a pipe, in a tank or in a bypass for flexible installation options.

Increased profitability. You know in real-time with precision the total weight of fuel delivered to the aircraft to avoid jettisoning fuel.

Flight safety. Continuous monitoring of viscosity enables the pilot to make sure the viscosity stays optimal during the flight to prevent engine relight difficulties. You can be sure to follow IATA – International Air Transport Association – specifications.

|

|

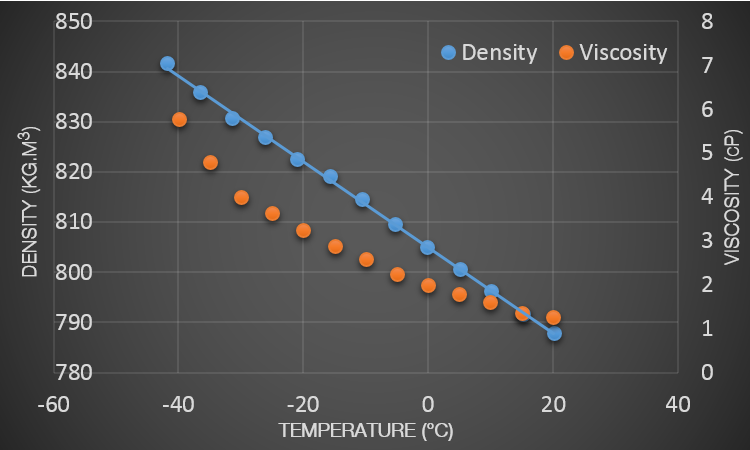

| Figure 1: Viscosity and Density measurements of Jet-A1 by DEVIL sensor | Figure 2 shows 5 successive temperature ramps performed with jet A-1 from ambient down to -40°C. Results show excellent DEVIL repeatability (typically 0.05 – 0.1cP) of the viscosity output |

Features:

- Online measurement of the liquid density, viscosity & temperature for real-time calculation of mass fuel delivered

- Fast and reliable digital communication capability

- Certified for use in hazardous areas

Still hesitating? Contact our technical engineers to discuss your project sales.wikatech@wika.com